- Home

- Discover...

- More about...

- Geotechnical / SSI tools

- Connecting with others

- Grillage modelling

- Steel frame design

- RC slab / wall design

- RC frame design

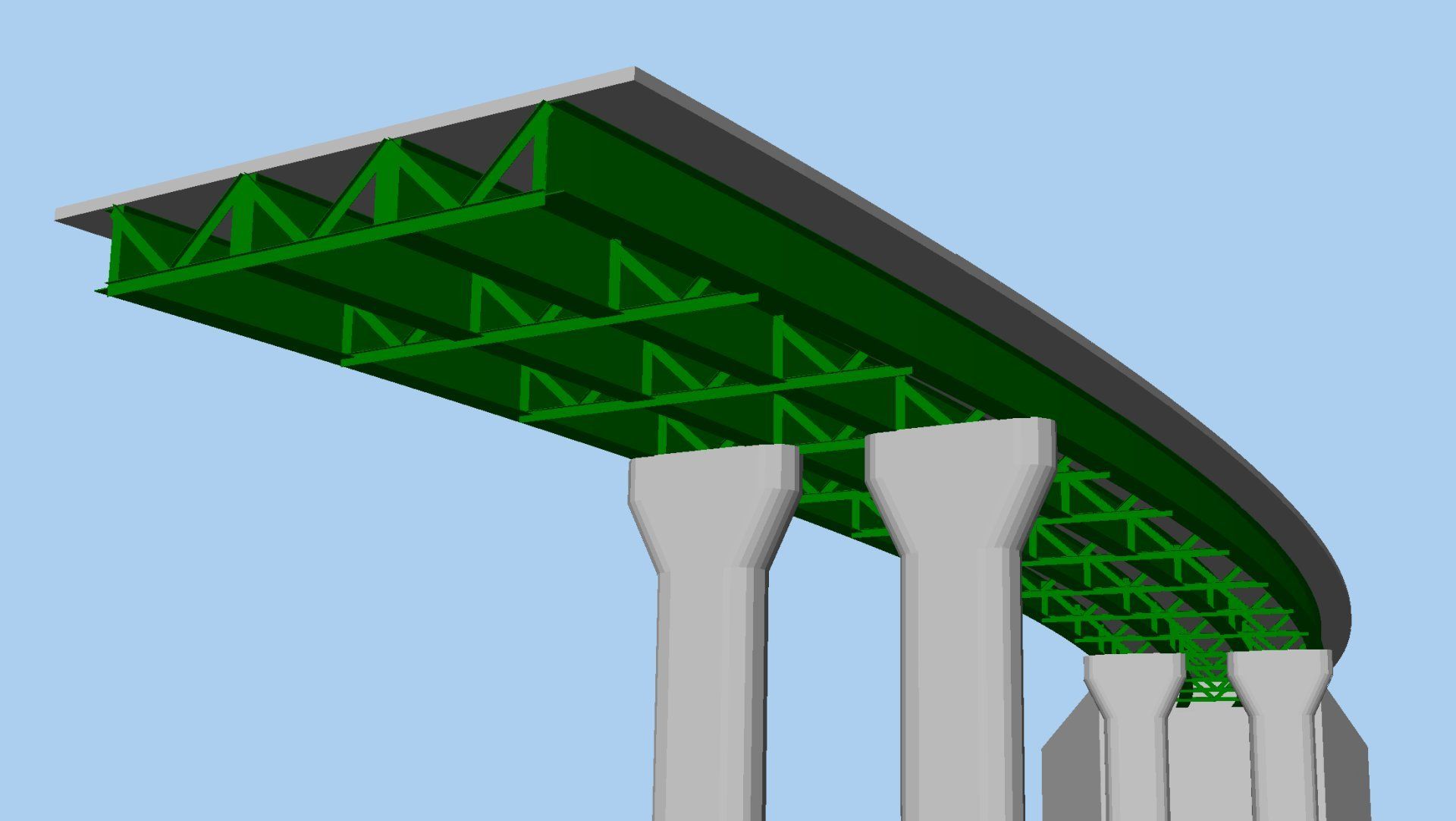

- Composite deck design

- Steel composite bridge wizard

- Post-tensioned bridge wizard

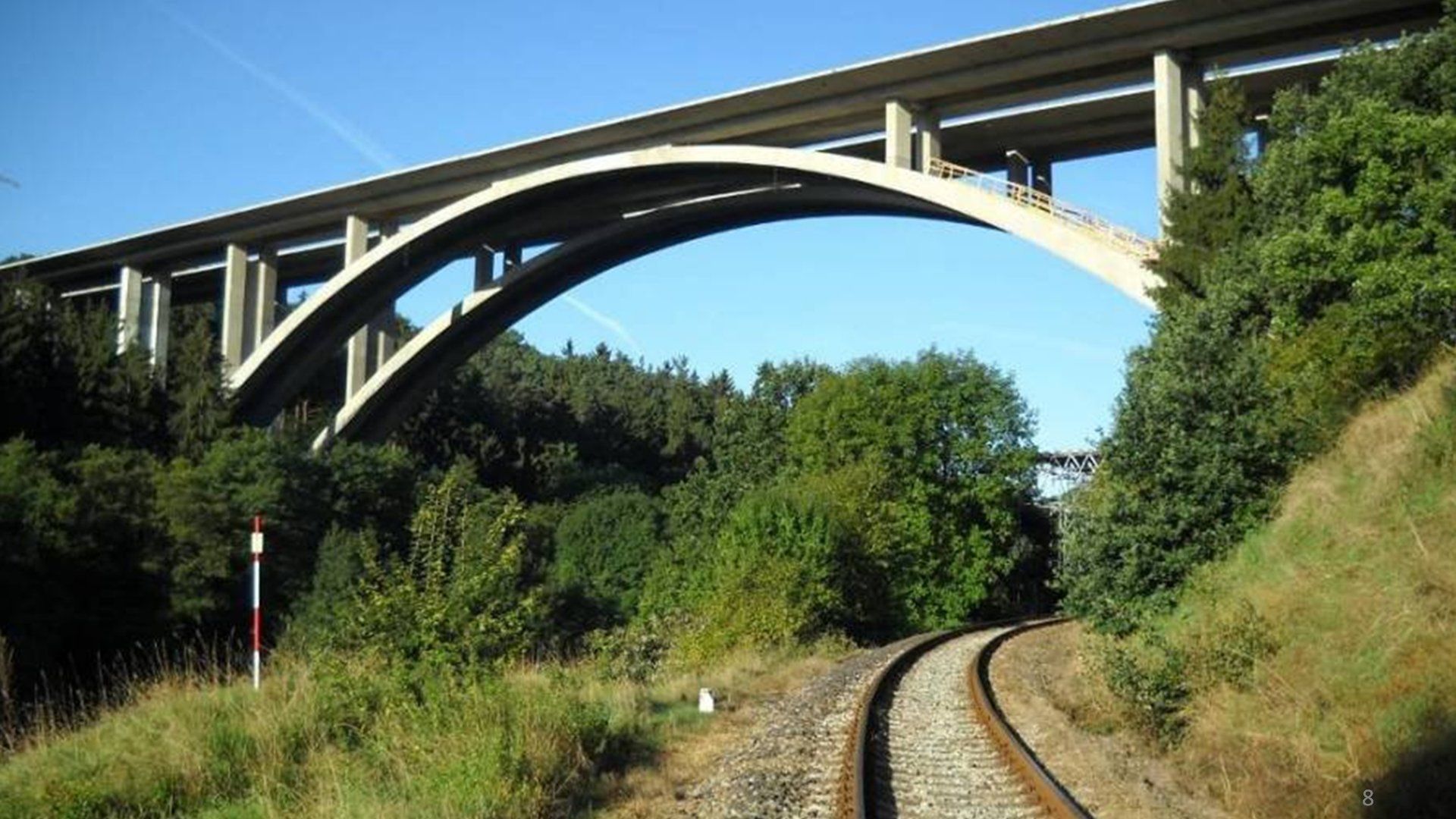

- Masonry bridge wizard

- Advanced concrete modelling

- Prestress / post-tensioning

- Load optimisation and combinations

- Rail infrastructure modelling

- LNG tank system

- Version 21.0 in detail

- Media...

- Blog

- Contact Us

Advanced concrete modelling

Advanced concrete modelling

LUSAS has long been known for its advanced analysis capabilities, with a concrete cracking and crushing material model developed over many years in collaboration with top researchers in the field.

- A time-dependent creep and shrinkage concrete material model allows for comprehensive analysis and better assessments of structures in service, and better predictions for concrete placed quickly or adjacent to existing material.

- For early age concrete, hygro-thermal analyses allow the determination of heat of hydration across a body of concrete, taking into account the availability of water for the exothermic reaction with time, based on the concrete mix, shape, exposed faces, insulated surfaces, environmental conditions etc. This avoids the use of “typical” heat generation curves, although these can still be drawn upon for comparison purposes.

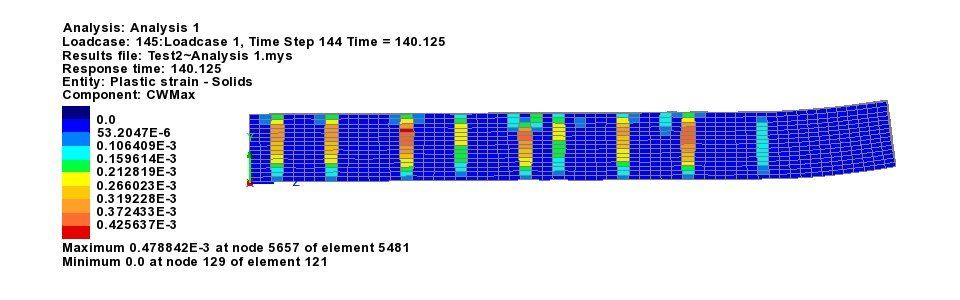

- Coupling the hygro-thermal analysis with a structural or “mechanical” analysis, the cracking, crushing, creep and shrinkage technologies are brought into the picture, allowing the determination of time- and age-dependent deformations, stresses, crack-widths and more, working to - and beyond the scope of - international Codes of Practice.

Hygro-thermal analysis

Capabilities

- Model the time (hydration) dependent behaviour of concrete from time of casting to old age.

- Take into account the time dependent environmental conditions when the concrete cures, such as daily cycles of temperature and humidity, to the desired degree of detail.

- Model the effect the formwork (and environment) has on the heat and moisture transfer to and from the concrete

- Predict the internal heat generated as the concrete cures so that any excessive temperature gradients that might cause the concrete to crack can be identified.

- Compute the amount of shrinkage in the concrete as it cures via the migration of moisture and the degree of saturation.

- Take into account the creep strains that occur during cure as the concrete is stressed.

- Model the evolution of properties E, fc, and ft.

- Predict failure when the concrete is fully (or partially) cured, and if the mesh is fine enough, obtain estimates of crack widths.

Comprehensive Nonlinear Concrete

To the code; beyond the code

- Cracking and crushing behaviour based on the latest research from Cardiff University, using strengths from your own sources or Code of Practice.

- Crack-widths assessed from first principles anywhere in the concrete, or bar-by-bar to EN1992.

- Creep and shrinkage to AASHTO, EN1992-1-1, CEB-FIP Model Code 1990, EN1992-2, fib Model Code 2010, IRC:112, and JTG 3362-2018, Zhu (1999) Mass concrete (China), or user-defined.

Nonlinear concrete in detail

Learn more about the nonlinear concrete material model.

Early Age Concrete: Hygro-thermal analysis

Rational, Flexible

- Model heat of hydration based on the availability of water, in preference to “typical” curves.

- Evaluate any shape, any concrete mix, any environmental conditions (varying with time).

- Cement types I, II, III, V or user-defined chemical composition are available. Include PFA and/or GGBS.

- Couple hygro-thermal with structural analysis to obtain time- and age-dependent deformations, stresses and cracking.

To the code; beyond the code

- Evaluate cracking and crushing with crack-width calculations from first principles or to EN1992, using the applicable strengths for the age of the concrete.

- Assess creep and shrinkage to EN1992 or CEB-FIP

- Move beyond outdated codes like BD28/87 or general approaches such as CIRIA C660.

- Carry out what-if scenarios such as keeping the air-exposed surfaces wet, or pre-cooling of the concrete before placement.

Associated advanced modelling features

Show me...

Modelling a dam

Illustrates the procedures involved in preparing a dam model for an initial linear static structural analysis. Activation and deactivation of elements is used to represent the staged construction process of pouring individual lifts of concrete.

Stresses in each lift are investigated using contour plots and a time-history response graph and an animation of the construction stages.

A separate model shows heat of hydration modelling involving the use of thermal material properties, with thermal temperatures and stresses arising from the analysis visualised.

In Version 21...

Learn more about...

-

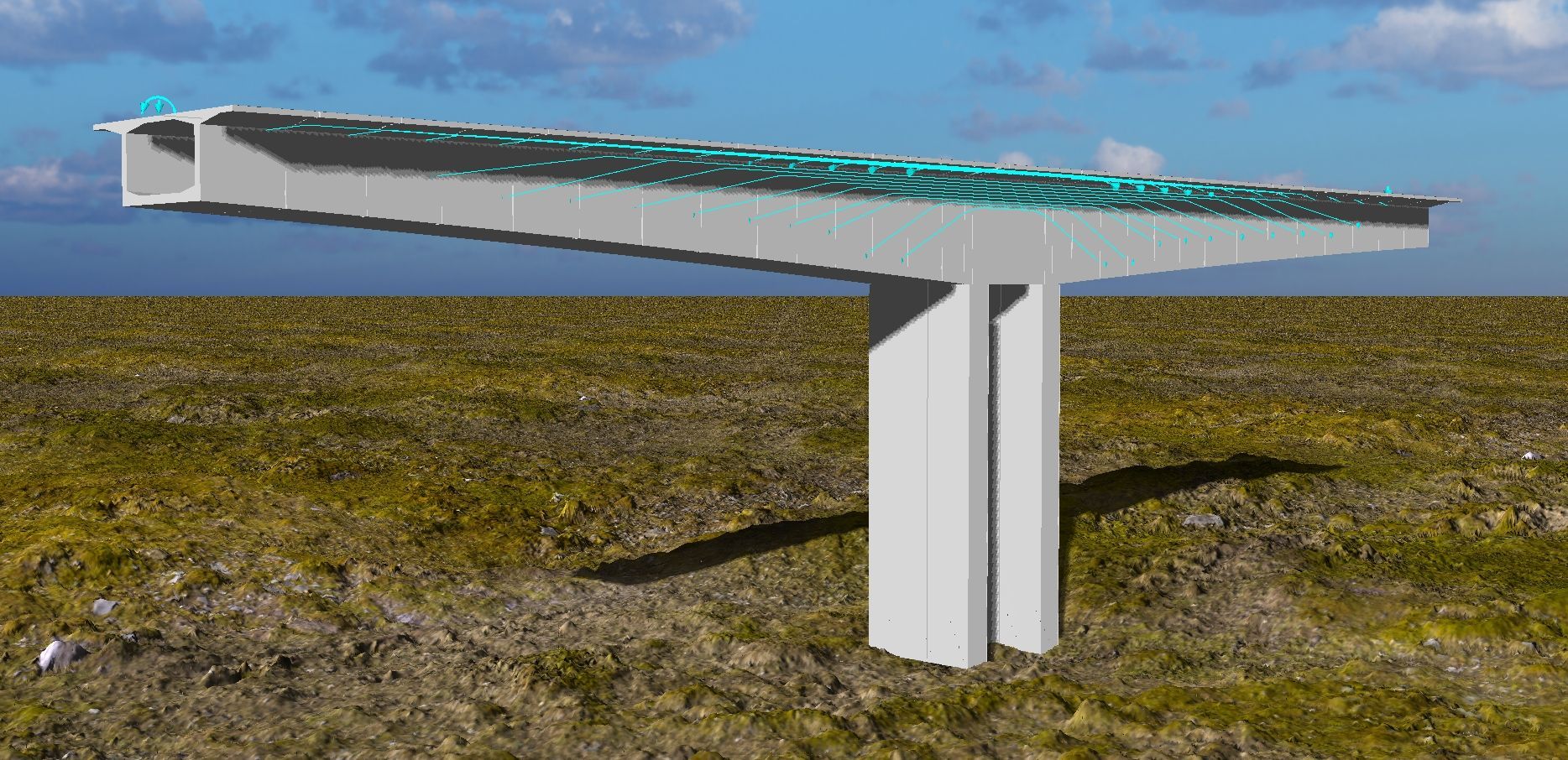

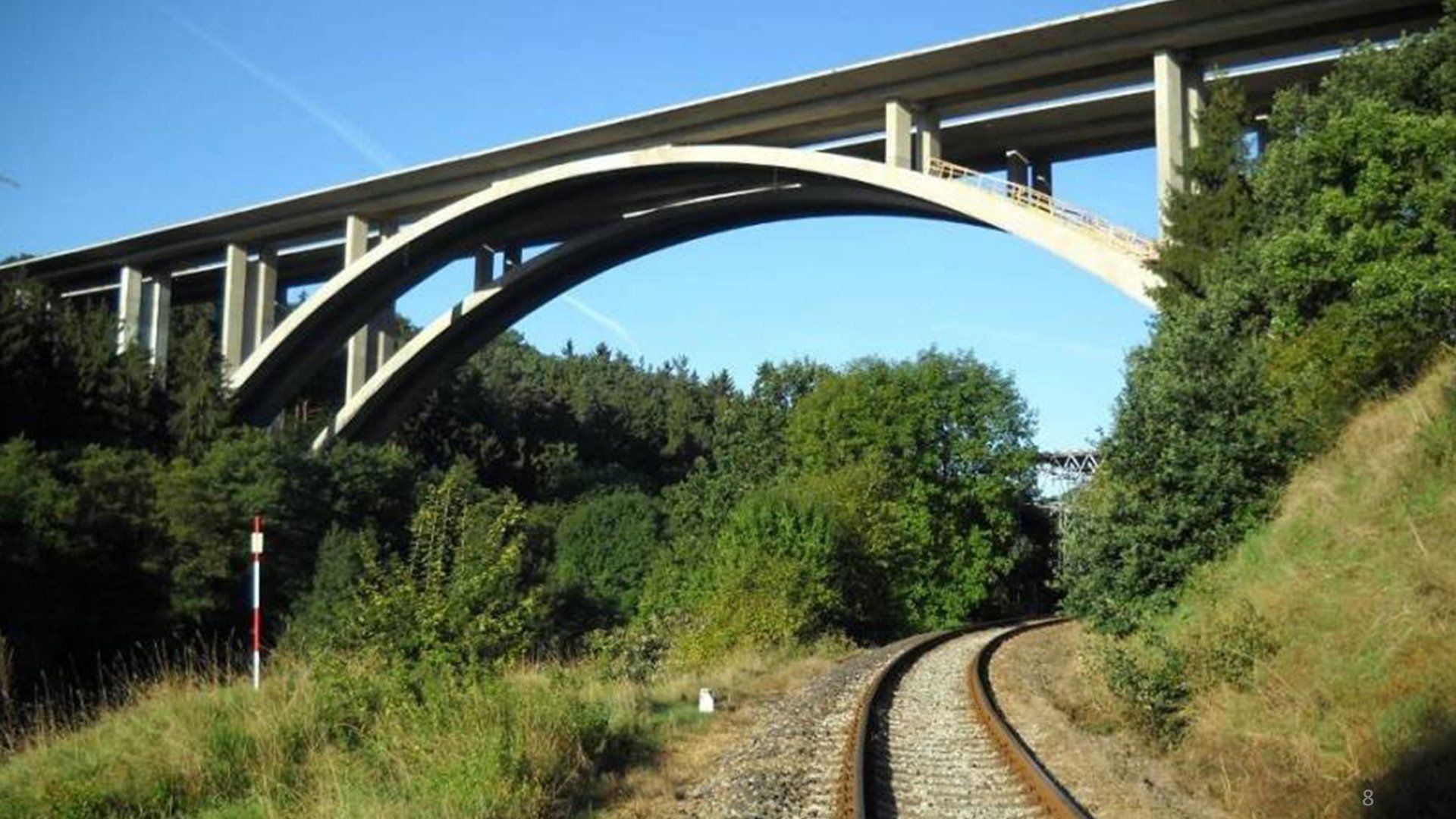

Post-tensioned Bridge Wizard

Button -

Connecting with others

Button -

Grillage modelling

Button -

Masonry Bridge Wizard

Button -

RC Slab / Wall design

Button -

LNG Tank System

Button -

Steel Composite Bridge Wizard

Photo By: John Doe

Button -

Composite Deck Design

Photo By: John Doe

Button -

Geotechnical / SSI

Photo By: John Doe

Button -

Steel frame design

Photo by: John Doe

Button -

RC frame design

Button -

Traffic Load Optimisation

Button -

Prestress / Post-tensioning

Button -

Advanced concrete modelling

Button -

Rail infrastructure modelling

Button

View more

For more information...

- For more details of LUSAS software products visit www.lusas.com

- To download LUSAS software visit the LUSAS User Area of the main website.

- Contact us via our contact form, or use Live chat, if available.